The Impact of Environmental Conditions on PT6A Engine Maintenance

The Pratt & Whitney PT6A engine is renowned for its reliability and versatility across various aviation applications. However, to keep this workhorse performing at its best, understanding how environmental conditions impact its maintenance is crucial. Different climates and operating environments can significantly affect the engine’s performance, longevity, and maintenance schedules. In this blog post, we will explore how these factors influence PT6A engine maintenance and offer tips on how to manage these effects effectively.

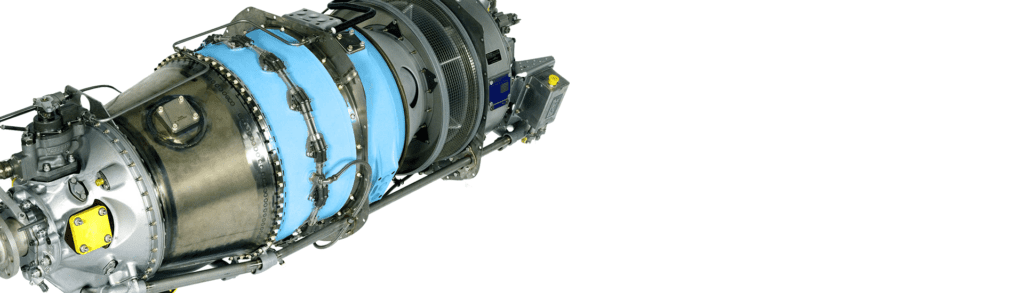

Understanding the PT6A Engine

Before diving into the environmental impacts, let’s briefly revisit what makes the PT6A engine special. The PT6A series, a turboprop engine known for its durability and efficiency, is commonly used in both commercial and military aircraft. Its design allows it to operate in various environments, but its performance and maintenance needs can be sensitive to external conditions.

How Environmental Conditions Affect PT6A Engine Maintenance

1. Temperature Extremes

- Hot Climates: Operating in high temperatures can lead to increased engine temperatures and stress on the cooling system. Heat can cause oil to degrade faster and may lead to accelerated wear on engine components. Regular oil changes, frequent checks of the cooling system, and monitoring engine temperatures are essential in such climates.

- Cold Climates: In cold environments, the risk of engine icing and slower oil flow can be significant. Preheating the engine before startup, using appropriate anti-icing additives, and ensuring proper lubrication during cold starts are critical practices to mitigate these effects. Frequently the use of salt can also potentially become an issue in colder climates so regular engines washes are highly recommended. See our post about engine washes for our recommendations.

2. Humidity and Rain

- High Humidity: Humid conditions can contribute to corrosion and oxidation of engine components. It’s important to ensure that the engine is properly sealed and to inspect for signs of moisture ingress. Regular cleaning and corrosion prevention measures can help maintain engine health.

- Rain and Water Exposure: Persistent exposure to rain can lead to water accumulation in critical engine parts. Regularly inspect and drain any water that may collect in the engine and ensure that the engine’s water seals are intact.

3. Dust and sand

- Arid and Dusty Conditions: Operating in dusty environments can lead to particulate ingress into the engine, which can cause abrasion and wear on internal components. Installing high-quality air filters and performing frequent filter changes, along with regular engine inspections, can help prevent damage from dust and sand.

- Desert Conditions: In addition to dust, desert environments may expose engines to extreme temperatures. Comprehensive checks and maintenance routines should account for both dust-related wear and temperature extremes.

4. Altitude

- High Altitude Operations: Engines operating at high altitudes face lower oxygen levels, which can affect combustion efficiency and increase the risk of engine overheating. Regular monitoring of engine performance and adjusting maintenance schedules to accommodate altitude-related stresses are recommended.

- Variable Altitudes: For engines that frequently transition between different altitudes, ensuring that the engine is properly tuned for varying air densities and monitoring for signs of performance degradation is important.

Adjusting Maintenance Schedules

Given the varied impact of environmental conditions, adjusting maintenance schedules is crucial for ensuring the longevity and reliability of the PT6A engine. Here are some key adjustments:

- Routine Inspections: Increase the frequency of inspections based on the severity of environmental factors. For instance, in dusty or high-humidity environments, more frequent checks for corrosion and particulate buildup are necessary.

- Lubrication and Fluids: Adapt the type and frequency of oil changes and fluid checks based on temperature extremes. Use synthetic oils or additives suited for the operating environment.

- Component Checks: Pay special attention to components like filters, seals, and cooling systems, which are more susceptible to environmental wear and tear.

Best Practices for PT6A Engine Maintenance in Varying Climates

- Regular Monitoring: Implement a robust monitoring system to track engine performance and detect issues early, especially when operating in challenging environments.

- Preventative Measures: Use environmental protection measures such as engine covers, dust filters, and corrosion-resistant coatings.

- Training and Awareness: Ensure that maintenance personnel are well-trained and aware of how different conditions impact engine care.

- Documentation: Keep detailed records of environmental conditions and maintenance activities to help identify patterns and adjust practices as needed.

Conclusion

The Pratt & Whitney PT6A engine is built to withstand diverse operating environments, but environmental conditions undeniably affect its maintenance needs. By understanding and adapting to these effects—whether dealing with extreme temperatures, humidity, dust, or altitude—you can optimize maintenance schedules and ensure the engine’s longevity and reliability. Implementing tailored maintenance practices and staying vigilant to environmental impacts will keep your PT6A engine running smoothly and efficiently, no matter where your aviation adventures take you.

Don’t forget that adhering to manufacturer-recommended maintenance intervals and procedures is imperative to mitigate the risk of in-flight failures and ensure the longevity of your engine. We always recommend consulting the OEM maintenance manuals, and more specifically the section related to Table 601, for further information.

For more information on this and other training materials, or boroscope services please contact our team at sales@bfgaero.com.

Don’t forget to follow us on LinkedIn to keep up with the latest BFG Aerospace news! If you would like more information on PT6A series engines contact us for more information, and as always, BFG Aerospace has you covered!