Understanding PT6A Engine Overhaul: When and Why

When it comes to maintaining the reliability and performance of your aircraft, the PT6A engine—one of the most popular turboprop engines in aviation—requires special attention. Overhauling your PT6A engine is a critical component of its maintenance lifecycle, and understanding when and why it’s needed can save you time, money, and ensure optimal performance. In this blog post, we’ll delve into the PT6A engine overhaul process, identify signs that indicate it’s time for an overhaul, and discuss the benefits of timely maintenance.

What is a PT6A Engine Overhaul?

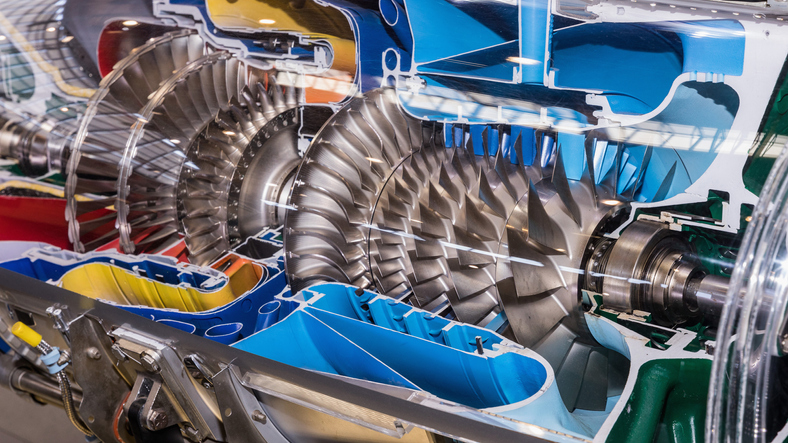

A PT6A engine overhaul involves a comprehensive inspection and refurbishment of the engine to restore it to like-new condition. This process includes disassembling the engine, cleaning, repairing or replacing worn components, and reassembling it to meet or exceed manufacturer specifications. The goal is to extend the engine’s operational life, ensure safety, and maintain performance standards.

Signs That Indicate It’s Time for an Overhaul

Besides the normal operating times established by the OEM (or an extended life program), recognizing the signs that your PT6A engine requires an overhaul is crucial for avoiding unplanned downtime and costly repairs. Here are some key indicators:

- Increased Oil Consumption: Excessive oil consumption can signal internal wear or seal failure, which may necessitate an overhaul.

- Power Loss: A noticeable decrease in engine power can be a sign of internal component degradation or efficiency issues.

- Unusual Noises: Any abnormal sounds, such as grinding or whining, may indicate worn bearings or other critical components that need attention.

- Frequent Maintenance Issues: If your PT6A engine is experiencing frequent breakdowns or requires constant repairs, it might be more cost-effective to opt for an overhaul.

- High Cycles and Operating Hours: Every engine has a recommended number of cycles and operating hours before an overhaul is needed. Regularly tracking these metrics is essential to staying ahead of maintenance requirements.

- Foreign Object Damage (FOD): depending on the extent of the damage a full overhaul may be recommended.

- Prop strike or incident.

The Overhaul Process

The PT6A engine overhaul process is a meticulous procedure that involves several steps:

- Engine Removal (often completed by the operator, prior to shipment into the shop): The engine is carefully removed from the aircraft, ensuring all connections are safely detached.

- Visual inspection: The engine is visually inspected to provide overhaul feedback and determine if there any obvious signs of damage or if anything is missing.

- Disassembly: The engine is disassembled, with each component inspected for wear and damage.

- Repair or Replacement: Worn or damaged parts are either repaired or replaced with OEM (Original Equipment Manufacturer) parts (or occasionally with PMA, depending on the regulatory bodies of the operator’s location) to ensure compatibility and performance.

- Inspection and Testing: All components are rigorously tested and inspected. This includes checking for cracks, wear, and performance issues.

- Reassembly: The engine is reassembled with precise attention to detail, adhering to manufacturer specifications.

- Testing: Once reassembled, the engine undergoes a series of tests to ensure it operates correctly and meets performance standards.

Benefits of Timely Overhaul

- Enhanced Reliability: Regular overhauls ensure your engine operates reliably, reducing the likelihood of unexpected failures and downtime.

- Improved Performance: An overhauled engine restores performance to its original specifications, enhancing fuel efficiency, power output, and overall operational efficiency.

- Cost-Effective Maintenance: While overhauls can be costly upfront, they can be more economical in the long run compared to frequent repairs and potential engine replacements.

- Increased Safety: A well-maintained engine reduces the risk of malfunction, ensuring the safety of your aircraft and its passengers.

- Compliance with Regulations: Adhering to overhaul schedules ensures compliance with aviation regulations and standards, avoiding legal and operational issues.

Conclusion

Understanding the PT6A engine overhaul process, recognizing the signs that it’s time for an overhaul, and appreciating the benefits of timely maintenance are essential for ensuring the longevity and performance of your aircraft. By staying proactive with your engine maintenance, you can enjoy enhanced reliability, performance, and safety, ultimately leading to a more efficient and cost-effective operation.

Don’t forget that adhering to manufacturer-recommended maintenance intervals and procedures is imperative to mitigate the risk of in-flight failures and ensure the longevity of your engine. We always recommend consulting the OEM maintenance manuals for further information.

For more information on this and other training materials, or boroscope services please contact our technical advisor Fernand Foisy at [email protected].

Don’t forget to follow us on LinkedIn to keep up with the latest BFG Aerospace news! If you would like more information on PT6A series engines contact us for more information, and as always, BFG Aerospace has you covered!