Comprehensive Maintenance Checklist for PT6A Engines: A Detailed Guide to Ensure Peak Performance

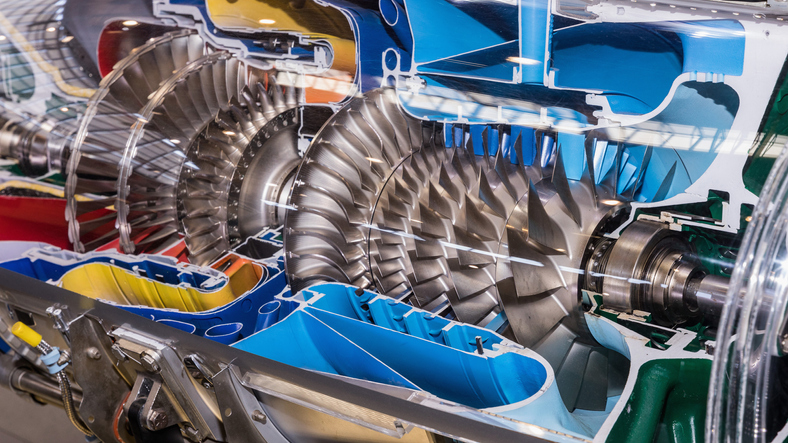

The PT6A engine, one of the most versatile and widely used turboprop engines in the aerospace industry, is renowned for its durability and reliability. However, like any high-performance machine, it requires regular maintenance to ensure optimal performance and longevity. For all aviation companies, MRO’s, enthusiasts, and operators alike, understanding the intricacies of maintaining PT6A engines is critical. This guide outlines a comprehensive maintenance checklist, including routine inspections, common wear points, and critical tasks to help you keep these engines in top condition.

Why Proper Maintenance of PT6A Engines Matters

Regular maintenance of PT6A engines is essential for several reasons:

- Safety: Keeping engines in peak condition reduces the risk of unexpected failures and increases overall flight safety.

- Performance: Well-maintained engines operate more efficiently, providing better fuel economy and power.

- Longevity: Proper care extends the lifespan of the engine, reducing the need for costly repairs and replacements.

Key Maintenance Intervals for PT6A Engines

Maintenance schedules for PT6A engines are typically divided into the following intervals:

- Daily/Pre-Flight Inspections

- 100-Hour Inspections

- 300-Hour Inspections

- 1,800-Hour Hot Section Inspections

- Overhauls at 3,000 – 3,600 hours (depending on your specific model and MM requirements)

- Special Inspections (condition-based)

Let’s dive deeper into each phase of the maintenance process.

Daily/Pre-Flight Inspections

Daily inspections are crucial to catching any issues early on before they escalate. Pilots and/or maintenance teams should perform a visual inspection of the engine and related systems before each flight.

Checklist for Daily/Pre-Flight Inspections:

- Check for leaks: Examine the engine for oil or fuel leaks.

- Inspect the intake: Ensure the air intake is clear of obstructions or debris.

- Propeller check: Inspect the propeller blades for damage, nicks, or cracks.

- Oil levels: Verify that oil levels are within the appropriate range.

- Bypass valve: Check for any fuel bypass indicator triggers, which may point to fuel contamination.

These inspections, while simple, are your first line of defense in maintaining engine reliability.

100 Hour Inspections

The 100-hour inspection is more detailed than a daily check and focuses on key components that are prone to wear and tear over time. This inspection is required after every 100 hours of operation.

Checklist for 100-Hour Inspections:

- Fuel nozzles: Remove and inspect the fuel nozzles for clogs or carbon buildup.

- Compressor section: Check the compressor blades for nicks, erosion, or corrosion.

- Ignition system: Inspect the igniters and ignition leads for wear or damage.

- Oil filter: Replace the oil filter and inspect it for metal particles that could indicate engine wear.

- Gearbox inspection: Ensure the accessory gearbox is free of leaks and excessive wear.

Paying attention to these components can prevent minor issues from turning into major repairs.

1,800 Hour Hot Section Inspections

At 1,800 hours of operation, a Hot Section Inspection (HSI) is necessary. This focuses on the internal components that experience extreme temperatures during operation.

Checklist for 1,800-Hour Hot Section Inspections:

- Combustion chamber: Disassemble and inspect the combustion chamber for cracks, erosion, or wear.

- Turbine blades: Check for any signs of cracking, warping, or erosion, especially on high-pressure turbine blades.

- Fuel nozzles: Inspect for carbon buildup and potential blockages.

- Thermal barriers: Inspect and replace thermal barriers as necessary.

Completing an HSI is critical to maintaining the engine’s performance and ensuring that it operates within safe temperature limits.

3,000 – 3,600 Hour Overhauls

Depending on the specific PT6A model, a complete engine overhaul is necessary after 3,000 to 3,600 hours of operation. This is the most comprehensive maintenance task, involving a full teardown and rebuild of the engine.

Checklist for 3,000-3,600-Hour Overhauls:

- Full engine teardown: The engine is completely disassembled to check for wear or damage to all components.

- Turbine blade inspection: Inspect turbine blades for cracking, warping, or erosion.

- Bearing replacement: All engine bearings should be inspected and replaced as necessary.

- Gearbox and reduction gear: Inspect for wear, and replace parts as needed to ensure smooth operation.

- Repairs and Replacements: Depending on the findings of the technicians and the life limits of the components, some pieces may need to be repaired and/or replaced.

- Re-assembly and testing: After overhaul, the engine is re-assembled and tested in a controlled environment to ensure it meets performance specifications.

Engine overhauls are essential for resetting the engine’s service life and ensuring long-term reliability.

Common Wear Points in PT6A Engines

While the PT6A is known for its reliability, there are several common wear points that should receive special attention during any inspection:

- Compressor Blades: Erosion, especially in sandy or abrasive environments, is a common issue.

- Fuel Nozzles: Clogs or carbon buildup can cause uneven fuel distribution, leading to performance issues.

- Turbine Blades: Over time, turbine blades can crack or erode, particularly in high-hour engines.

- Bearings: These are subject to wear due to the high stresses they endure and must be checked regularly.

- Oil System: Regular oil sampling can detect contamination or excessive wear on internal components.

Critical Maintenance Tips for PT6A Engines

- Parts, Components and Accessories: Always ensure that the components going into your engine are compliant with your local regulatory authority’s policies. Some governing bodies will require only OEM parts, and others may be more flexible which may allow for cost savings in replacement parts. It’s important to verify with your local authorities and your technicians about these, and as always when in doubt consult the OEM Maintenance Manual for details.

- Keep Detailed Records: Accurate documentation of maintenance tasks can help predict future repairs and ensure compliance with regulatory requirements.

- Proper Lubrication: Use only manufacturer-recommended lubricants and change the oil at the specified intervals.

- Environmental Considerations: If operating in harsh environments (high dust, saltwater, sand, humidity, etc..), more frequent inspections of the intake, compressor, and fuel system are required.

Final Thoughts

Maintaining the PT6A engine is not only about adhering to prescribed schedules but also about being proactive and paying attention to common wear areas. A well-maintained engine provides more than just reliable service—it ensures the safety of your operations, enhances performance, and maximizes the return on your investment. Don’t forget that adhering to manufacturer-recommended maintenance intervals and procedures is imperative to mitigate the risk of in-flight failures and ensure the longevity of your engine. We always recommend consulting the OEM maintenance manuals. Don’t forget that adhering to manufacturer-recommended maintenance intervals and procedures is imperative to mitigate the risk of in-flight failures and ensure the longevity of your engine. We always recommend consulting the OEM maintenance manuals for further information.

BFG Aerospace takes pride in offering expert PT6A engine services, including engine management of routine maintenance, overhauls, and inspections. Trust us to keep your fleet in peak operating condition.

For more information on this and other training materials, or boroscope services please contact our team at sales@bfgaero.com.

Don’t forget to follow us on LinkedIn to keep up with the latest BFG Aerospace news! If you would like more information on PT6A series engines contact us for more information, and as always, BFG Aerospace has you covered!