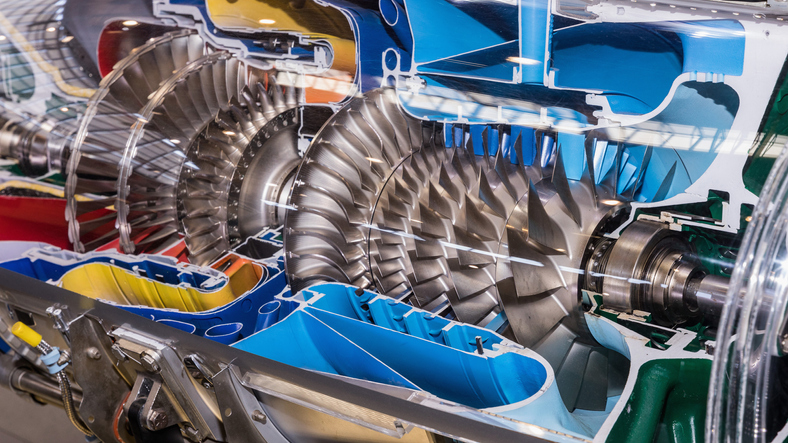

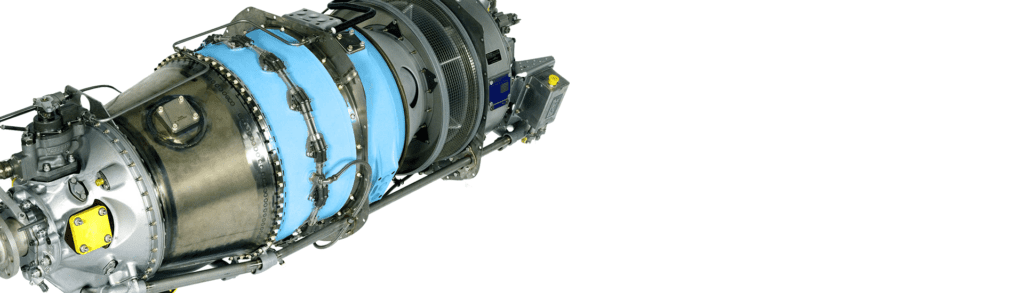

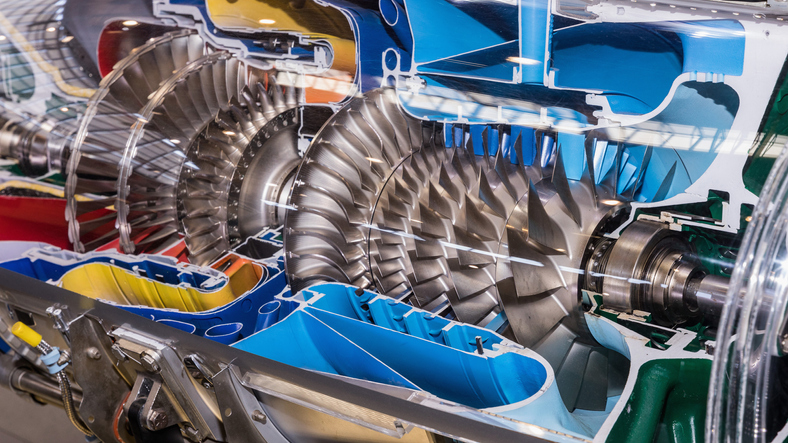

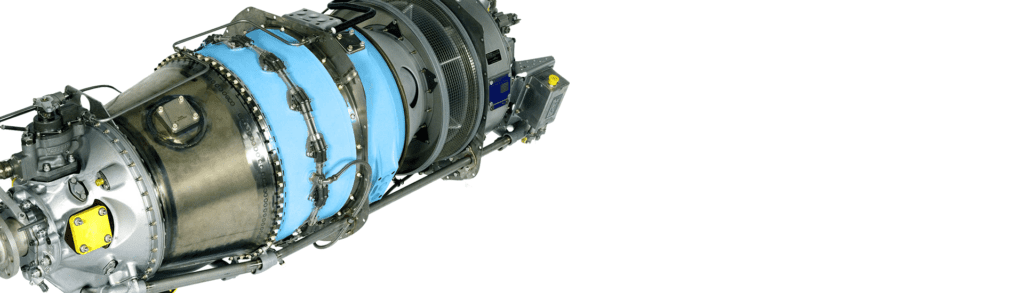

Comprehensive Maintenance Checklist for PT6A Engines

Maintaining the reliability and performance of PT6A series engines requires a thorough and consistent maintenance approach. In this article, BFG Aerospace outlines a detailed checklist designed to assist operators and maintenance professionals in ensuring optimal engine functionality. Key focus areas include regular inspections, adherence to manufacturer-recommended maintenance intervals, and the significance of environmental considerations on engine health. By following this comprehensive guide, stakeholders can mitigate the risk of in-flight failures and extend the service life of their PT6A engines.

The Impact of Environmental Conditions on PT6A Engine Maintenance

The Pratt & Whitney PT6A engine is renowned for its versatility and reliability across diverse operating environments. However, varying environmental conditions—such as extreme temperatures, humidity, dust, and altitude—can significantly influence maintenance requirements. This article delves into how these factors affect engine performance and outlines strategies for optimizing maintenance schedules to ensure longevity and reliability.

Understanding PT6A Engine Overhaul: When and Why

The PT6A engine is renowned for its reliability and performance, but like all mechanical systems, it requires periodic overhauls to maintain optimal functionality. This article delves into the critical aspects of the PT6A engine overhaul process, helping operators recognize the signs indicating the need for an overhaul and understand the benefits of timely maintenance. By staying proactive with engine maintenance, operators can ensure enhanced reliability, performance, and safety, ultimately leading to more efficient and cost-effective operations.

Fuel Nozzle series part 4 – Final Inspections

The removal of nozzles process is much like any other procedure related to the meticulous care of your PT6A engines, it should be done with proper care and while paying particular attention to detail.

Fuel Nozzle series part 3 – Inspections and Checks

The removal of nozzles process is much like any other procedure related to the meticulous care of your PT6A engines, it should be done with proper care and while paying particular attention to detail.

Fuel Nozzle series part 2 – Removal

The removal of nozzles process is much like any other procedure related to the meticulous care of your PT6A engines, it should be done with proper care and while paying particular attention to detail.

Fuel Nozzle series part 1 – Simplex vs Duplex

One often overlooked crucial element to properly maintain your PT6A engine is the fuel nozzles, which can contribute greatly to your engine’s overall health.

Engine Starting and ITT temperature

Monitoring the health and well being of your engines is an essential part of your daily operations. Maintaining the value of your assets and saving money in the long term on shop visits, as well as regularly scheduled maintenance activities are key points to a successful business. Engine starting and ITT temperature are key aspects […]

Fuel Nozzles for PT6 series engines

When it comes to PT6, there are two main types of Fuel Nozzles; the Simplex and the Duplex. With Simplex fuel nozzles, you have two different nozzles; primary and secondary. Each nozzle has a single orifice. Simplex nozzles are typically set up as either all primary (in some engines), or in a ratio of 7 […]

Igniter Plugs

Did you know that a very small and often overlooked component can play a major role on the performance of your engine? The Igniter plugs (or Spark Igniters) need to be inspected regularly to ensure serviceability. These little components are key during the engine start sessions. If left unchecked they can become unserviceable, having a […]